Pelleting feed and concentrates offers a number of advantages for poultry and livestock producers. Pelleting can reduce feed waste, lessen the time allocated to eating (allowing more energy to be dedicated to growth) and improve gain and feed efficiency. Pelleting also helps with feed logistics — improved feed flow through bins, less dust formation, reduced ingredient separation during storage and less space required for storage. However, these benefits are achievable only if the pellet is of good quality. A poor-quality pellet with a large number of fines won’t return the same benefits and will have a low benefit-cost ratio.

Sorbiam™ Improves Flowability

Purpose-made pellet binders can be added to feed to improve the pellet durability index and the overall quality of the pellet. However, premium feed additives like mineral-based Sorbiam™ (available in North America only) can offer producers more than pellet quality improvements. Sorbiam promotes efficient production economics for poultry and livestock through the maintenance of a healthy gastrointestinal tract. Because Sorbiam is produced as microgranules, flowability is improved throughout feed production. Sorbiam is also available as Sorbiam XL, which is the same product manufactured as slightly larger-sized microgranules.

Sorbiam Pellet Durability Research

Recent research from Kansas State University (Manhattan, KS) suggests that Sorbiam can help improve pellet durability as well as flowability. Two methods, the tumbling box and Holmen durability tests, were used to determine if Sorbiam can improve the pellet durability index (PDI).

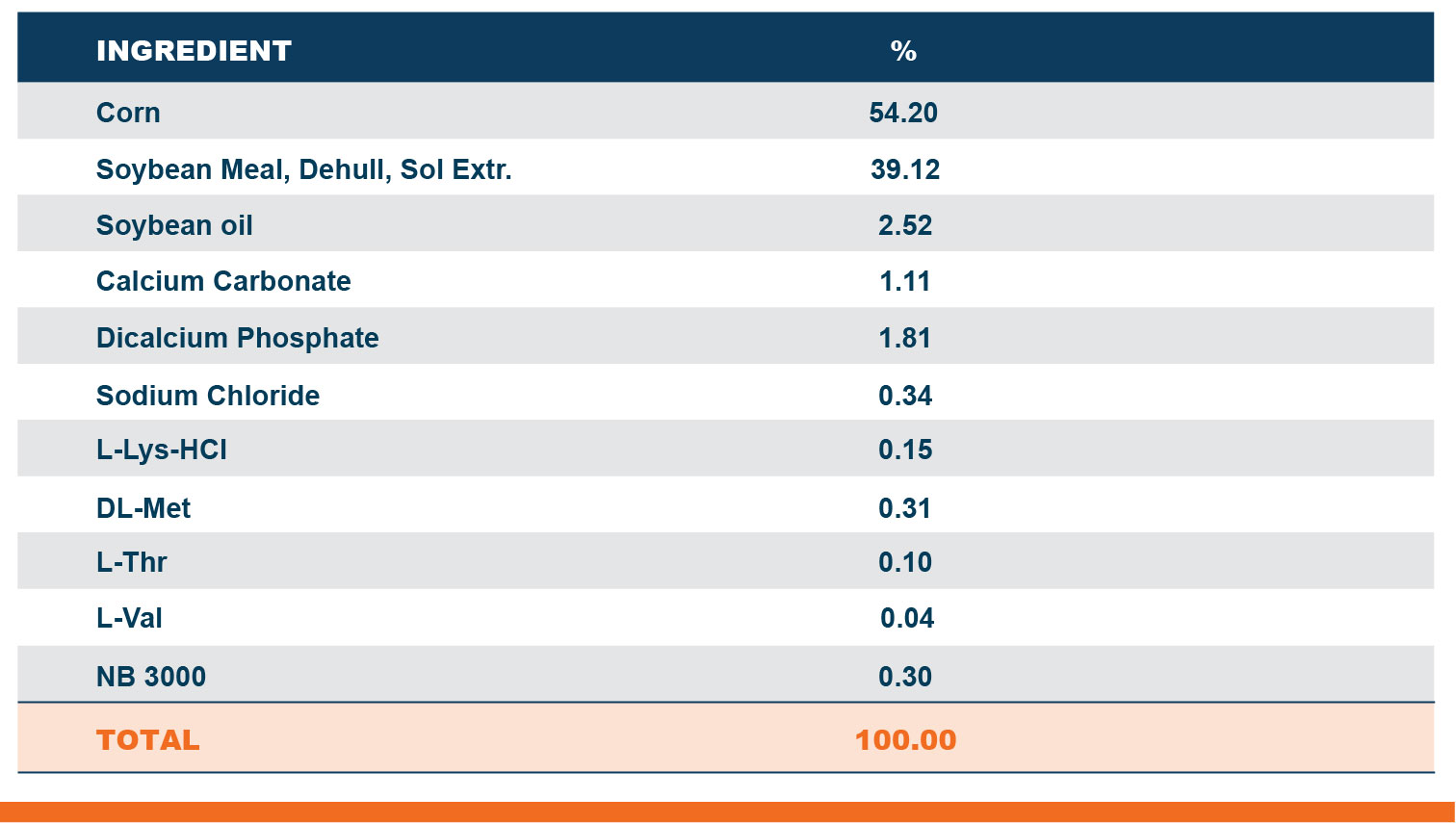

The basal diet was formulated with 2.52% soybean oil (Table 1). It had a production rate of 34 pounds/minute and a conditioning temperature of 82°C (180°F). Sorbiam was included at 0.1% in half the tested pellets (replacing 0.1% corn).

Table 1: Basal diet formulation for pellet durability testing

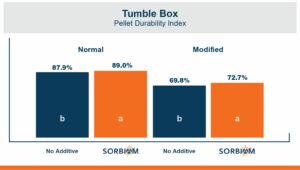

For the tumbling box traditional method, sieved pellets were placed in the tumbling can device and tumbled for 10 minutes. The samples were then removed, sieved and weighed, and the percent of whole pellets calculated. For the modified tumbling box method, three hex nuts were added to the tumbling chamber to create a more abrasive test.1

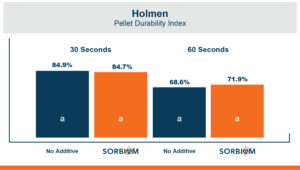

The Holmen durability test uses air to create the abrasion of pellets rather than the physical action that occurs in the tumbling box method1. To start the test, a weighed sample of screened pellets were added to the test chamber. The pellets were agitated by forced air for 30 or 60 seconds, then removed, sieved and weighed; and the percent of whole pellets was calculated.

For the tumbling box method, adding 0.1% Sorbiam to the formulation significantly improved the PDI for both the traditional and the modified procedures (increased PDI by 1.1% and 2.9%, respectively; Figure 1). For the 60-second Holmen durability test, there was a numerical improvement of 3.3% in the PDI when Sorbiam was added to the diet (Figure 2).

Figure 1: Sorbiam significantly improved the pellet durability index for both traditional and modified tumble box methods. Different letters within tumbling method indicate a significant difference (P < 0.05).

Figure 2: Sorbiam numerically improved the pellet durability index in the 60-second Holmen durability test. Different letters within tumbling method indicate a significant difference (P < 0.05).

Pelleting has many production and logistics advantages — but only if good-quality pellets are produced. In this study, adding Sorbiam to the pellets helped increase pellet durability, an important contributing factor to pellet quality. For more information on Sorbiam, contact your local Amlan representative.

Reference

1Stark, C. and Fahrenholz, A. Evaluating Pellet Quality, K-State Research and Extension, https://bookstore.ksre.ksu.edu/pubs/MF3228.pdf