Oil-Dri® Corporation of America has been active in the animal health market since the 1980’s with products designed to help feed flowability and pellet binding. But in 2007, Oil-Dri took a leap — a well-informed, scientifically-backed leap — further into the animal health market with the registration of the Amlan International brand and the official launch of their animal health business. Fifteen years later, Amlan International is a successful global brand that helps poultry and livestock producers optimize intestinal health and add value to their operation. So why did Oil-Dri, a company founded on a garage floor oil adsorbent, decide to invest in animal gut health solutions? And what does the future look like for Amlan?

Creating Value for Animal Health Producers

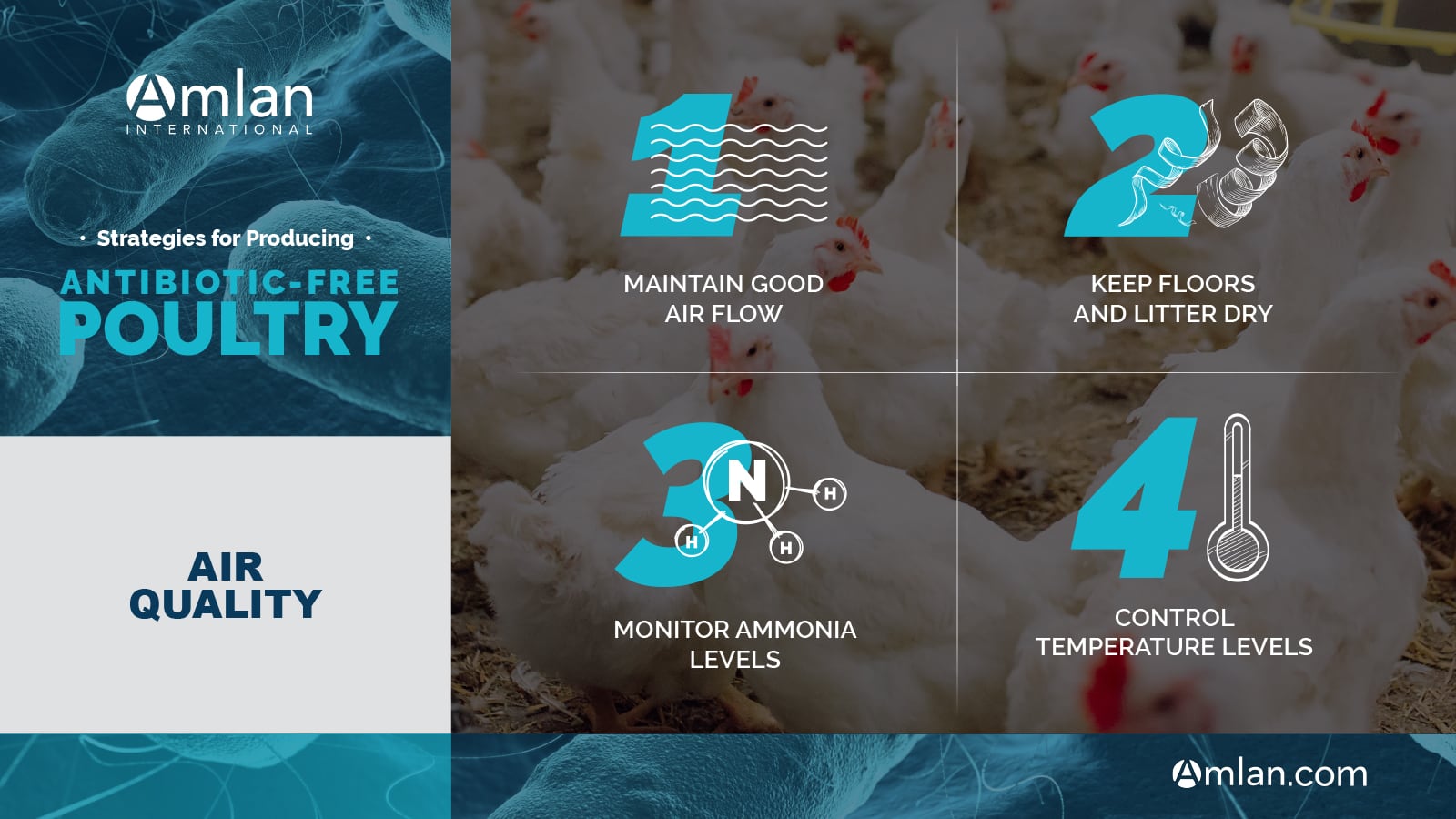

Consumer demands and concern over antimicrobial-resistant pathogens have created a global push toward antibiotic-free and natural animal protein production. But this change in production has also created the need for natural solutions to help manage the health and productivity of flocks and herds. As Dan Jaffee, President and CEO of Oil-Dri and President and General Manager of Amlan, explains, Oil-Dri saw the opportunity to create value for animal protein producers by leveraging an Oil-Dri-owned mineral to develop novel, natural feed additive solutions under the Amlan brand.

“We realized there was a market need, and Oil-Dri had an incredible natural solution to the problem. Our clay naturally does amazing things; but then when we combine our clay with our multi-million-dollar research investments, in our core lab and our new microbiology lab, we’ve been able to do some incredible things. And we’re really just at the beginning.”

—Dan Jaffee, President and CEO of Oil-Dri, President and General Manager of Amlan

As the animal health business of Oil-Dri, we take full advantage of the benefits that vertical integration brings, including control over the quality of our mineral and ensuring consistency of supply for our customers. We also leverage the 80 years of Oil-Dri mineral science expertise, and we share the values and business ethics of Oil-Dri.

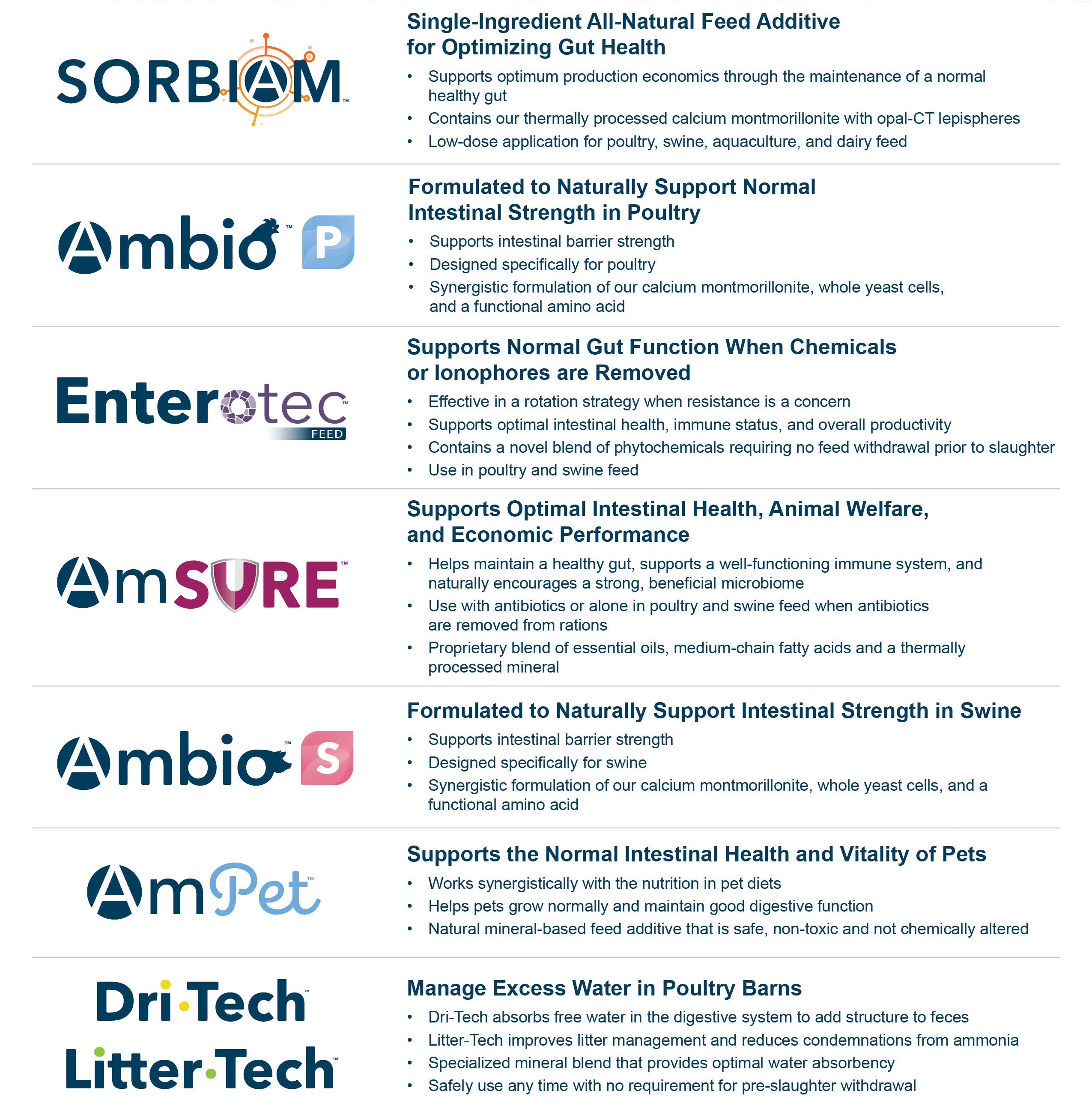

A Broad Range of Natural, Value-Adding Products

Amlan started with just two products, sold internationally outside of North America — biotoxin binding Calibrin®-Z and aflatoxin-binding Calibrin-A. Both products are made from our single-source calcium montmorillonite that undergoes proprietary thermal processing tailored for each product. It’s our mineral’s natural properties and our proprietary processing technique that make our mineral-based products stand out from other clay additives in the market.

Investing heavily in research and development has allowed us to expand our international product range by combining natural ingredients with our mineral to develop synergistic intestinal health solutions for production animals. This included the 2015 launch of Varium® for poultry and NeoPrime® for swine, which help reduce the level of pathogenic challenge in the intestine, strengthen and energize the intestinal barrier and stimulate intestinal immunity. The technology behind Varium and NeoPrime is patented in Brazil, Indonesia, Korea, the European Union, the United States and China, with other countries pending.

Most recently we expanded our international product portfolio with the launch of Phylox® Feed, a natural alternative to anticoccidial drugs and vaccines and NeutraPath®, a natural pathogen-control product (available in select markets). In 2021, Amlan also launched a broad portfolio of products specifically for North American producers. And we’re not done — we have more innovative products in our research pipeline that will continue our efforts to optimize animal intestinal health and provide value for producers.

Your Animal Intestinal Health Partner

Innovative products are a great start for a new business, but we see customers as partners, not numbers on invoices, so we also needed knowledgeable technical service specialists and a strong sales team to support our mission of creating value for our customers. Our team helps customers achieve their production goals by integrating rations with the best Amlan solutions for each situation. As Dan Jaffee mentions in the video below, this includes trialing products first to show customers the true value Amlan can bring to their operations.

Growing Our Future and Yours

Our goal for the future is to continue investing in innovation to continue developing natural solutions to industry challenges that can help producers drive profits naturally. You can hear Dan’s thoughts on the future of Amlan in the video below. Everyone at Amlan shares Dan’s excitement about the intestinal health solutions we are bringing to the animal production industry and the value our products offer for producers. To learn more about Amlan, our innovations and our team, visit our Who We Are page.