Amlan welcomes Kory Duerst, as a leading expert representing Amlan products in the U.S. dairy market.

In a one-on-one with Kory, and an introduction to our customers, we asked him to share his background, his view of the dairy industry, and why he decided to work with Amlan.

Q: How Did You End Up Working in Dairy?

A: “I have grown up immersed in the dairy industry. Our family has a century farm in Wisconsin, and I graduated from the University of Wisconsin River Falls with a degree in dairy science. It was the values that I, like every farm kid, learned about – the value of a hard day’s work and being able to ‘see’ your successes. Agriculture, specifically the dairy market, is an industry that I am blessed to work in and enjoy being able to give back to.”

Q: What Keeps Your Love for the Industry Alive?

A: “As to why I continue to be inspired to work in dairy daily, it is the people. You won’t find a better group of people who care other than the producers who produce the beef and milk we enjoy daily.”

Q: How have you seen the Dairy Industry Evolve?

A: “Over the last 20 years that I have been in the dairy industry, it has changed a lot. A big change is the size of farms; going from 100 cow stall barns to farms of 100,000 milking cows. And from the days of 2 row pull type choppers to 900 horsepower self-propelled custom harvesters. The dairy industry is growing and expanding in size and speed, but the values it is rooted in have not changed. I see more attention focused on healthier cows and reduced dependence on hormones and antibiotics. Today, I see farms producing 110+ pounds per cow daily. Data and technology are driving the majority of progress and change. The ability to measure and adapt quickly is speeding these changes too. I am not sure how, but I am certain AI will play an integral part in the next decade.”

Q: With Amlan being new to the U.S. Market, tell us how you came to know about Amlan and represent them.

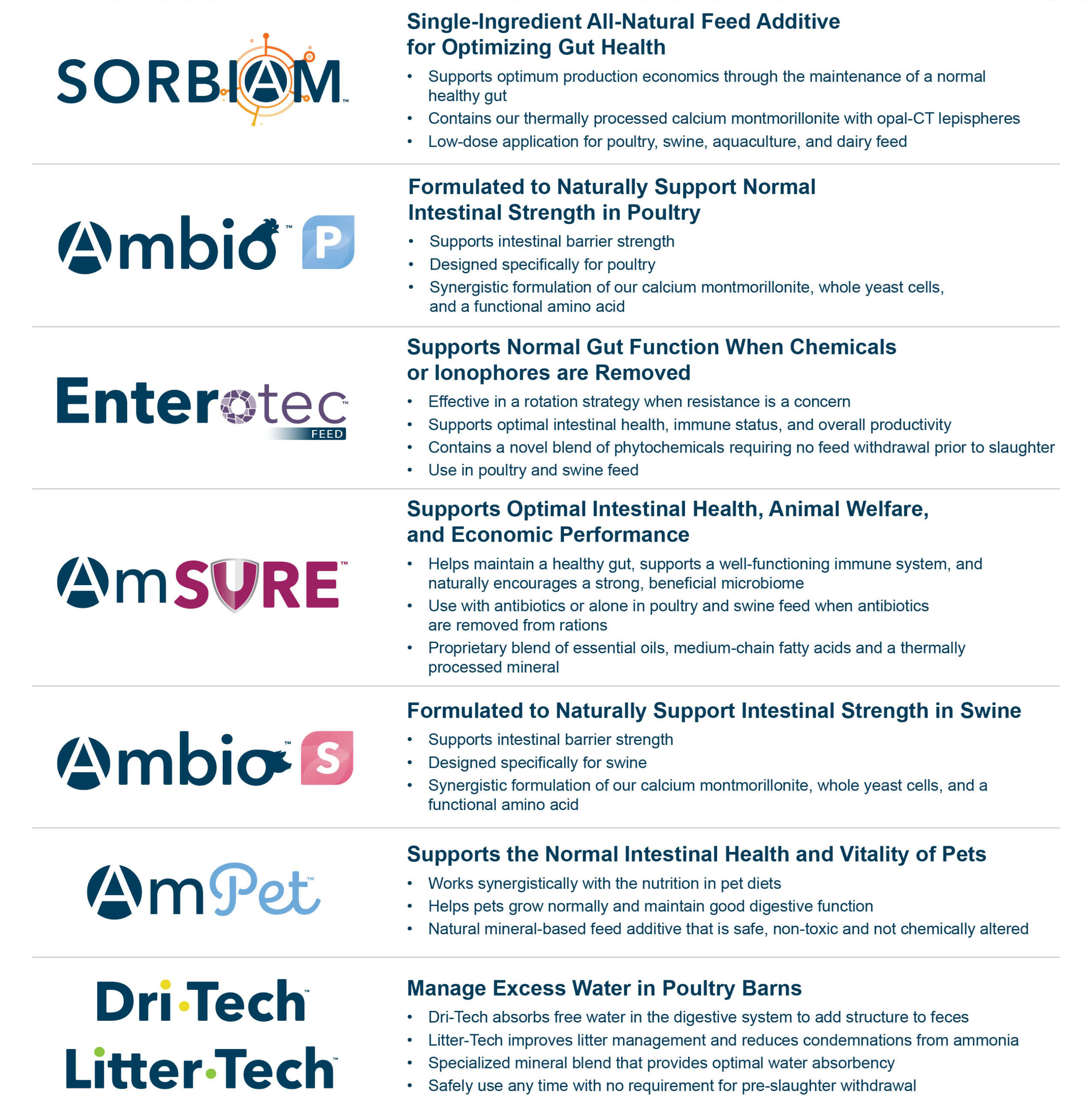

A: “Amlan was highly recommended to me by a university professor who had experience with Sorbiam XL. Dairy is a difficult industry to truly know if products work as advertised. I am always impressed when the data used to present product performance is 3rd party tested and validated. With Amlan’s Sorbiam XL product, feed mills will experience a very nice granulated and flowable product. It reduces dust and bridging in micro machines at a very cost-competitive price and provides overall better health and reproduction, drivers for an improved dairyman’s bottom line.”

To learn more about Sorbiam XL and how it helps support economic performance in dairy cattle, contact Kory Duerst at info@amlan.com or visit amlan.com.

Kory Duerst is the principal of Core Functional Ingredients, an independent, non-exclusive sales agent promoting Amlan products in North America.