It was a challenging year for everyone around the world, but for the poultry and livestock industries, the forecast for 2021 is encouraging. Let’s take a look back at production and consumer trends from last year and look at what the expectations are for this year. We will also recap some of our news stories from 2020 and share exciting new developments for 2021.

Record Chicken Meat Production

Global chicken meat production continued to increase in 2020; it’s a trend that will persist into 2021 according to the USDA, who predicts that a record 102.9 million tons to be produced. China will lead the growth but gains in Brazil, the EU, US and India are also expected. Brazil is also expected to increase exports by expanding shipments to the Middle East and Sub-Saharan Africa.

Pork Production Expected to Rebound

Swine production was impacted by two viral diseases in 2020: African swine fever (ASF) and COVID-19. However, according to the USDA, global pork production is forecasted to be 4% higher in 2021, as countries affected by ASF rebuild herds. Economic improvements and recovery of the food and restaurant service sectors should also improve demand for pork products.

Regionally, the USDA forecasts that increased domestic consumption will have pork production in Brazil set to increase 4% in 2021. While China is quickly rebuilding herds, production is expected to still be 25% lower than pre-ASF levels. Similarly, Vietnam and the Philippines are showing production recovery. However ASF continues to be a challenge in the Philippines. Taiwan was officially recognized as free from foot and mouth disease without vaccinations by the OIE in June 2020, but classical swine fever is still a concern for export pork markets.

Consumers Trends and Reduced AGP Use

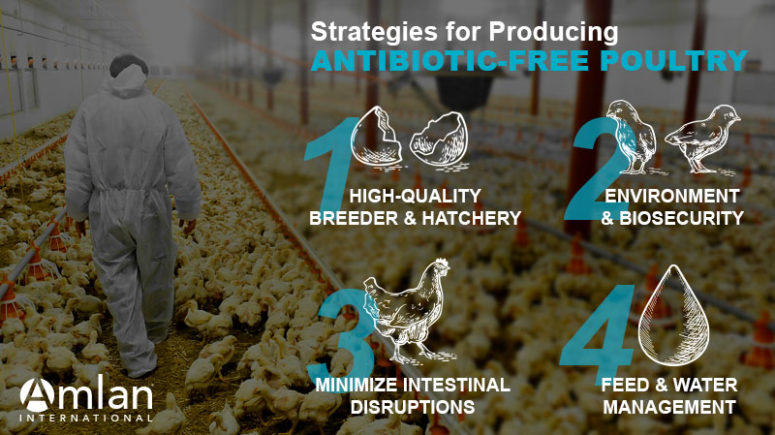

While global pork and poultry meat production is forecast to increase in 2021, the type of products consumers are purchasing may see a shift if trends from this year continue. Consumers are wanting healthy and safe products and are seeking claims-based meat options that have labels such as “all-natural” and “free-from.”

Along with consumer demand for “all-natural” products, the concern over multi-drug resistant and mutant bacteria has kept the reduction of antimicrobial use for growth promotion purposes a top priority for global livestock and poultry producers. Brazil banned the use of three antibiotics (tylosin, tiamulin and lincomycin) as growth promoters in 2020, aligning with OIE, FAO and WHO-supported policies.

Patented Natural Alternatives to AGPs

As demand for alternatives to AGPs increases, we are continuing to invest in next-generation technology that provides natural mineral-based feed additives for gut health and production efficiency. Last year, Amlan, which is the animal health business of Oil-Dri Corporation of America, a leading global manufacturer and marketer of sorbent minerals, announced that EU and US patents were issued in relation to formulation of the additives, Varium® for poultry and NeoPrime® for swine. A similar patent was issued in China in 2018 and additional patents are expected to be granted in the near future.

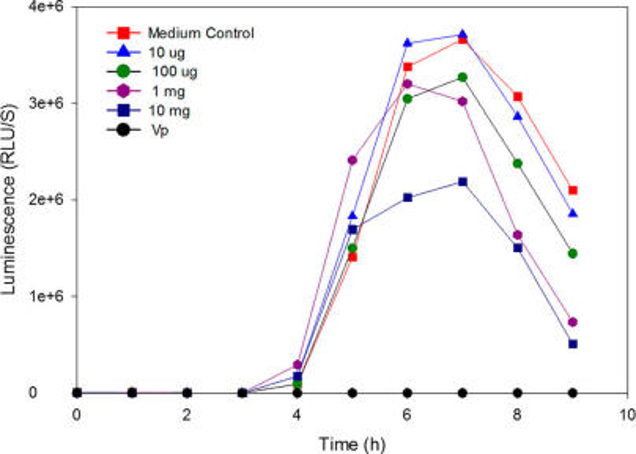

The patents provide a methodology for using a natural, mineral-based formula to mitigate the effects of exposure to pathogenic bacteria and the disease-causing toxins they produce, which damage gut health and function.

Amlan’s Leadership Team Expands

Our investment in intestinal health products strengthened last year with the appointment of Fred Kao to the newly created role of Vice President of Global Sales. Mr. Kao brings 20 years of expertise in building strong relationships with key integrators in the animal protein business around the globe, including Europe, Middle East, African and Asia Pacific regions.

Mr. Kao is working to build the sales and technical service team to offer more specialized and expert support to our customers. To support this goal, we recently welcomed the following people to our team:

- Heath Wessels, Director of Sales, North America

- Harold Zhou, Director of Sales, China

- Dr. Kreangkrai “Pong” Sangthongdang, Country Manager, Thailand

- Ricardo Ivanovski, Technical Service Specialist, Brazil

- Julio Aguila, Regional Key Account Manager, Mexico

- Andres Soto, Regional Key Account Manager, Mexico

- Sissi Fang, Sr. Marketing Specialist, China

- Summer Xiao, Logistic Assistant, China

- Wang Huarui, Area Sales Manager, North China

- Teng Yingyun, Area Sales Manager, South China

New Natural Health Solutions for Poultry and Livestock

Our scientists are experts in developing advanced mineral-based technology using our owned, unique mineral and proprietary thermal activation process. This year we will continue to develop natural, efficacious feed additives for protein producing animal disease management, and we are excited to announce that two new products will soon be commercially available in select countries.

While 2020 was certainly a difficult year in many ways, everyone at Amlan is dedicated to helping poultry and livestock producers reduce their production challenges. By investing in state-of-the-art technology and developing next-generation mineral-based products and services, we are providing producers with innovative solutions to improve the health and production efficiency of their flock or herd. To learn more, visit https://amlan.com/products/