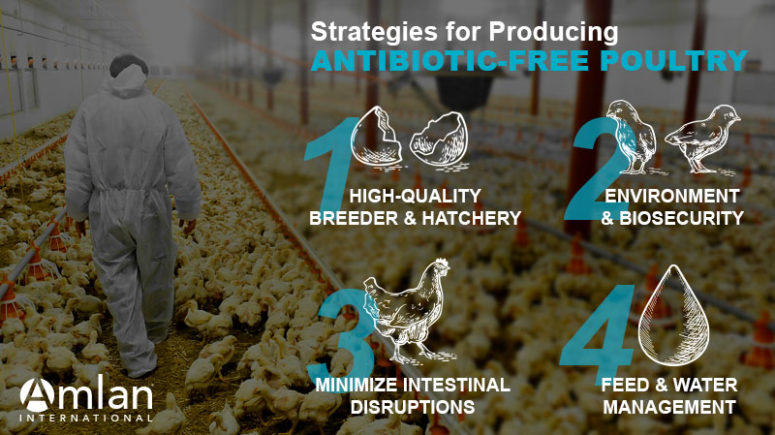

As producing poultry meat that can be labelled antibiotic free (ABF) or No Antibiotics Ever (NAE) becomes more common and desirable, poultry producers are looking for ways to mitigate major poultry diseases in a safe, sustainable and profitable way.

At Amlan, we consult with poultry producers around the world. Those who are transitioning to ABF production are concerned about whether their breeder and grow-out operations can remain competitive, profitable and free from performance-robbing intestinal diseases such as necrotic enteritis. To be successful, a whole-production-system approach that factors in housing management, water quality and biosecurity is needed to maintain bird performance while managing profit margins.

Improved health of broilers starts with the breeder and hatchery

Since breeders can transfer intestinal microbes and immunity to their progeny, companies that are transitioning to ABF production are paying close attention to ensuring intestinal health is adequate in breeders and that vaccination programs are effective. Effective management means watching cross-contamination from the breeder program to the broiler program, including ensuring the hatched eggs are clean and not creating cross-contamination issues by fogging and cleaning too much.

Good litter management is another housing practice to not only get chicks off to a good start, but also to reduce disease challenges. Management practices will vary depending on many factors. In general, cleaning out hatcheries once per year is a good practice. Litter amendments can be used to reduce ammonia and bacterial challenges in-between clean-outs. We also find that removal of caked/wet litter along with windrowing or composting litter is beneficial between flocks.

Improve house environment and biosecurity

Proper environmental conditions are the foundations of effective ABF poultry production and can help cut down on disease issues. Environmental stress due to heat, cold, or very dry or very humid air can affect feed intake and intestinal motility, causing reduced digestibility. We recommend that producers ensure optimum temperature, air velocity and relative humidity according to the age, phase of production and size of the birds.

A large-scale poultry producer with which we have discussed ABF practices emphasizes downtime between flocks, whether or not it’s an ABF system. This producer recommends 14 days of rest before putting another flock in. Then, effective flock management helps reduce stress and disease. Reducing the density of the flock gives the birds more room and greater air circulation, which results in less litter moisture — all leading to lowered challenge. Further, good house ventilation is key for ABF programs to maintain litter moisture below 30 percent, and to minimize condensation and caking.

The most efficient production facilities also focus on nutrient uptake management. While controlling intestinal diseases is important, focusing on nutrient absorption is equally important. Inadequate nutrient absorption contributes to the severity of many diseases. Appropriate feed digestibility is key to broilers’ overall health and can help control microbes and resultant diseases.

The best biosecurity practices include bio-exclusion — limiting visitors, vehicles and equipment that visit other poultry farms. Also, implement bio-containment practices, such as isolating the houses and controlling the entry of insects, rodents, and wild birds and other animals to the houses. These are some of the practices that can help prevent the introduction of new infections in flocks. In a future Amlan blog post, we will deliver more details on these practices.

Feed and water management

Nutritionists know that a balanced diet and sufficient water consumption are essential to improve digestibility. For best results, producers tend to use high-quality feed and minimize drastic changes to the feed program (changing from corn to wheat, for example) within a generation of broilers. Some poultry operations recommend feeding larger and coarser particle sizes (800 to 1,000-micron grind size) while avoiding powdery or fine-textured feeds results in better enzyme release in the gut.

We’ve found that it’s also important to formulate the feed on a digestible amino acid basis and reduce crude protein levels to prevent an overload of Clostridium in the lower gut and the incidence of necrotic enteritis. Producers should also consider supplementing feed with exogenous enzymes and, to further strengthen their effect, additives such as phytases and xylanases.

Other producers say that, if allowed, adding animal protein meal to the diet helps lower costs and reduce excess potassium. They also provide a good mineral source and promote a better amino acid balance. If you go that route, poultry by-product meal, feather meal and poultry fat are good feed ingredients.

Finally, good water quality and management is critical. Adding acidified copper sulfate and hydrogen peroxide to the drinking water during challenging times, such as during the necrotic window, is also recommended.

Maintaining gut health and minimizing intestinal disruptions are key

Preventing coccidiosis and necrotic enteritis are normally the main concerns during ABF production. Without antibiotics and even ionophores, it’s more of a challenge to keep these diseases under control.

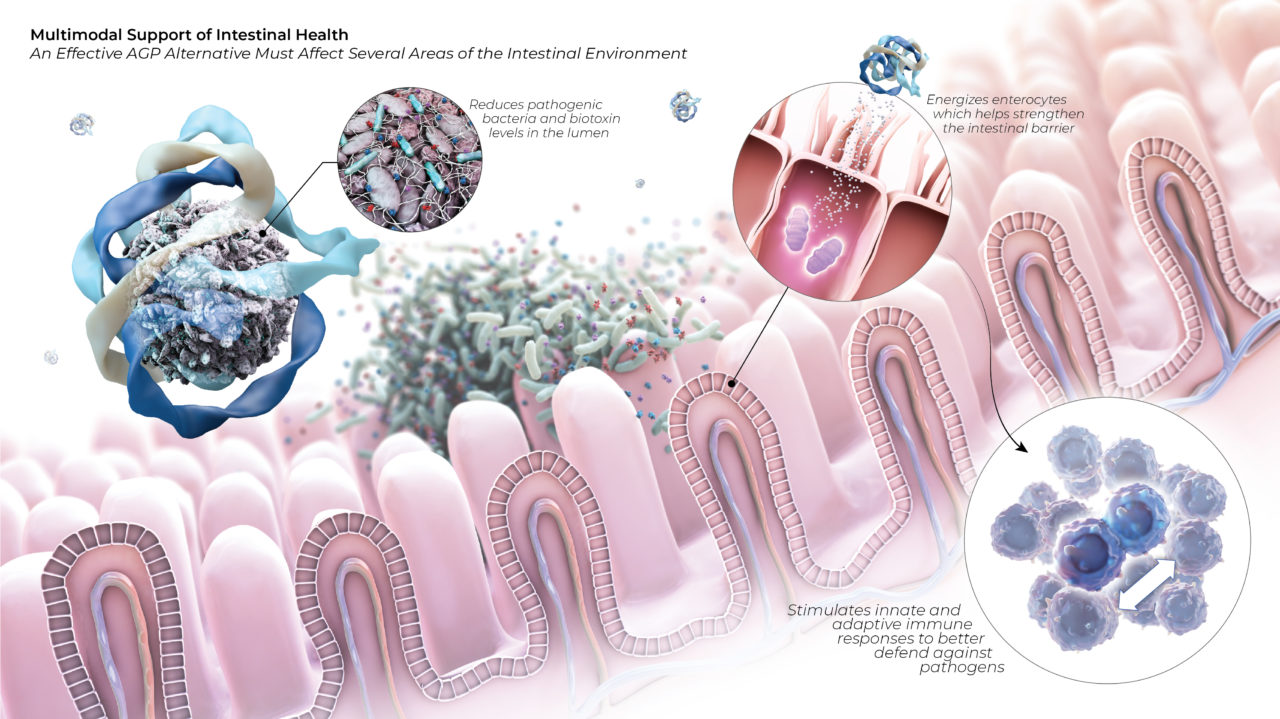

At Amlan, we talk a lot about the important role that the gut flora plays in supporting disease management and enhancing the immune system. In addition to a balanced diet and good housing conditions as described earlier, feed additives and minerals can help maintain a healthy microflora in all gut regions.

Certain formulated feed additives are designed to use different and (ideally) synergistic modes of action to achieve desired responses. These products are typically tested by a team of specialists to determine the optimal formulation, so growers don’t have to experiment. They include prebiotics, probiotics, enzymes, organic acids, minerals and other additives that can be used successfully to manage gut health instead of AGPs. Formulated feed additives that combine the right ingredients to replace one or more other additives and help birds grow efficiently are just what today’s broiler producers need.

Varium® is a patented feed additive used across the word in antibiotic-free poultry production to achieve similar outcomes as AGPs, often replacing one or more additional feed additives being used as alternatives to AGPs. Varium’s performance has been observed in multiple controlled studies and field trials and is helping commercial producers improve production efficiencies by improving feed conversion and weight gain and decreasing mortality.

It takes the right combination of best management practices to achieve a productive and profitable ABF poultry facility. We’re here to help provide you with the knowledge and technology to make a difference in your operation. Download a helpful, printable guide that summarizes the above best practices here, and check Amlan’s Education Center frequently for future posts on best production practices and natural feed additive programs that enhance intestinal health and improve efficiency in ABF poultry production.