Antibiotic-free (ABF) poultry production has its benefits — it increases market opportunities for producers and, perhaps more importantly, it helps reduce the emergence of antimicrobial resistant pathogens. But ABF production also brings with it a new set of challenges. One of the biggest is how to control the pathogens that reduce flock health and production efficiency, now that subtherapeutic levels of antibiotics can’t be used.

Stopping pathogens from entering the poultry house in the first place goes a long way in controlling disease outbreaks. But most pathogenic agents associated with common enteric poultry diseases are ubiquitous in the environment, meaning their management focuses more on control than eradication. In this post we discuss the importance of biosecurity and environmental management in controlling pathogens in ABF production systems. We also present data on NeutraPath®, a natural feed additive available in select international markets that has multiple modes of action against enteric pathogens.

Prevent Diseases Spreading

People are the biggest risk factor for introducing pathogens into a flock. For this reason, limiting visitors and wearing personal protective equipment in the barn are typically standard practices in poultry facilities. People traveling to the farm should also disinfect their shoes and vehicle floorboards when arriving and leaving the facility. Keeping rodents and insects out of the barn and preventing wild birds from contaminating open water sources are other key control points for effective biosecurity.

Create an Uninviting Environment for Pathogens

Water in the poultry barn can easily become a vector for microbial contamination. The nutrient-rich water lines and the warm environment of the poultry house are ideal growing conditions for bacteria and other pathogens. Therefore, water lines should be flushed regularly and cleaned between flocks, and water storage tanks routinely cleaned to prevent microbial growth.

Managing moisture and ammonia levels in poultry litter is also critical for reducing disease challenges and keeping birds healthy. This includes supplying adequate ventilation and regularly checking for water line leaks. Dry litter lessens the risk of disease, reduces morbidity and condemnations, and helps ammonia stay at acceptable levels. Windrowing the litter between flocks can help reduce the pathogen load because it heats the litter and allows the surrounding floor to dry out. Wet droppings due to poor intestinal health also increase moisture and ammonia in litter, which is another reason why supporting optimal intestinal health in birds is vital to production success.

NeutraPath®: A Natural Pathogen Control Product

As well as making the environmental conditions less favorable for pathogen growth, targeting the pathogens themselves is a key part of preventing enteric disease outbreaks in poultry. Traditionally, this was achieved by administering subtherapeutic levels of antibiotics, but natural, non-antibiotic products are now available for use in antibiotic-free production systems.

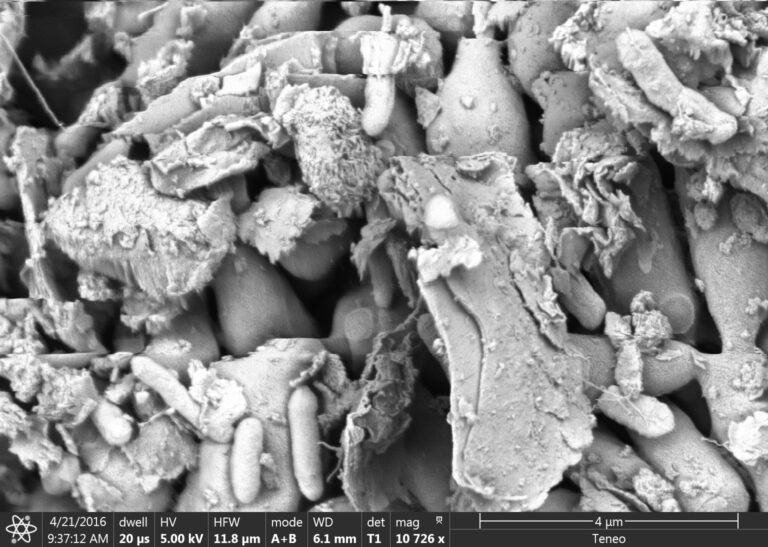

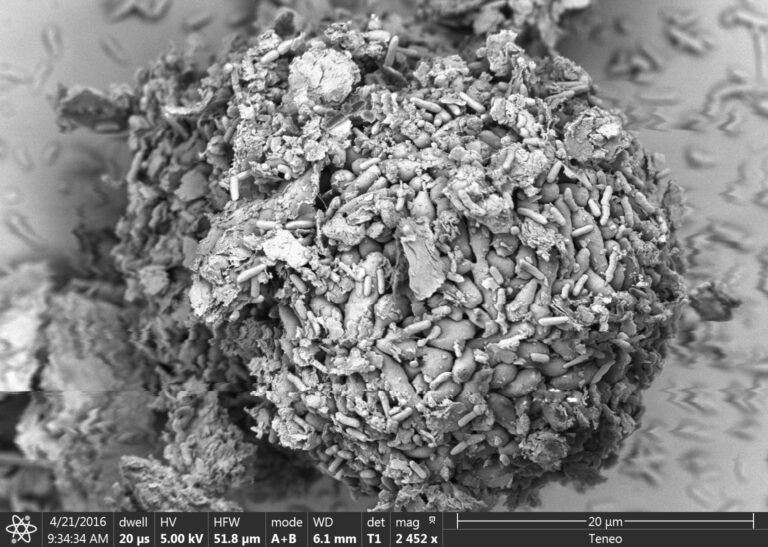

NeutraPath uses multiple modes of action to increase livability and improve feed conversion in antibiotic-free poultry. Using a proprietary and coactive blend of essential oils, fatty acids and Amlan’s proprietary mineral technology, NeutraPath reduces pathogenic bacterial load and colonization, and improves intestinal health and structural integrity, all of which contribute to improved performance and increased production yields.

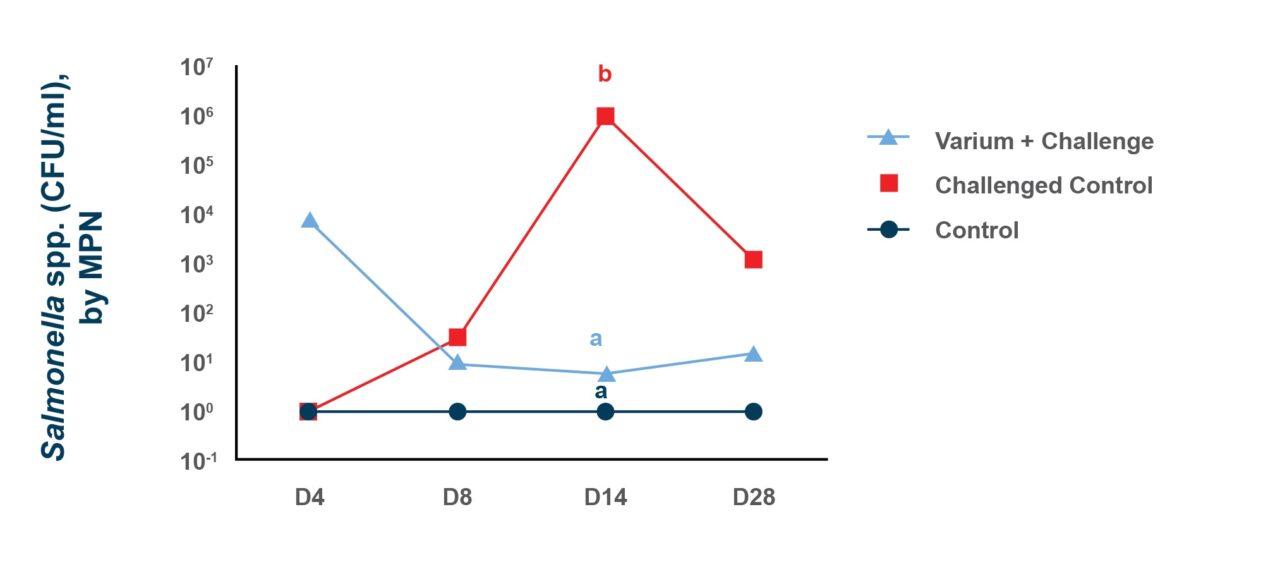

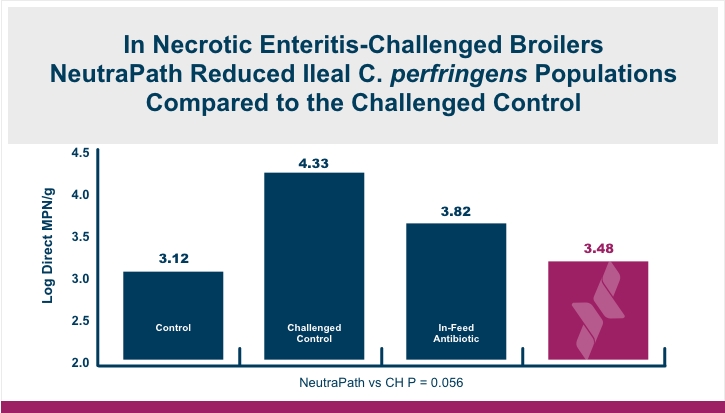

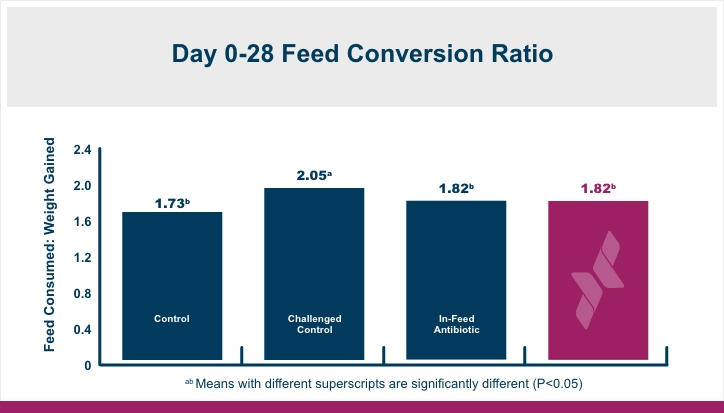

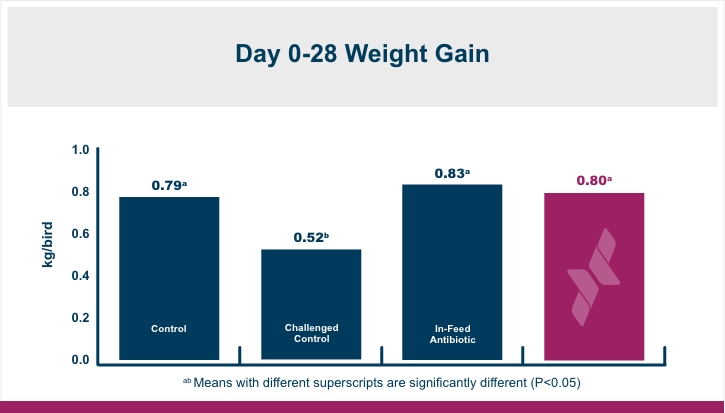

The ability of NeutraPath to control pathogens has been proven in multiple studies, including in research published in Poultry Science. In the Poultry Science study, NeutraPath exhibited a potent antimicrobial effect against Salmonella enterica serovar Typhimurium strain PHL2020 and reduced its intestinal colonization. In another study, NeutraPath reduced ileal Clostridium perfringens populations compared to the challenged control (Figure 1). Feed conversion ratio and weight gain results ensued that were similar between NeutraPath and an in-feed antibiotic (BMD) and were significantly better than the challenged control (Figure 2).

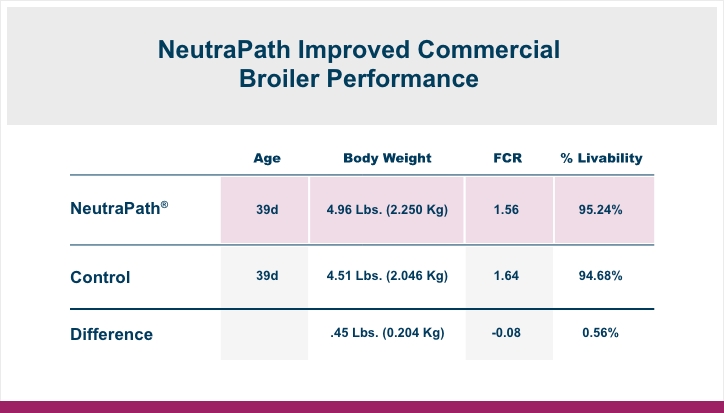

NeutraPath doesn’t just perform under pathogen-challenged conditions, however. In a side-by-side commercial broiler house study for an integrated broiler producer in the southern United States (54,000 birds per house), NeutraPath performed better across all parameters measured, including a 0.56 percent increase in livability (Table 1).

Creating unfavorable environmental conditions for pathogens can help reduce enteric disease outbreaks in poultry. To further control pathogens, NeutraPath can be incorporated into rations to strengthen intestinal health and reduce the intestinal pathogen load. For more information on NeutraPath or to set up your own NeutraPath trial, contact info@amlan.com.